Fuel moisture clutch manufacturer: working principle and characteristics of fuel filter

2023-07-05

Recently, many netizens asked what is the working principle and characteristics of the oil filter? Want to know, then today the fuel moisture clutch manufacturers will share with you, what are the characteristics and working principle of the fuel filter? Let's take a look:

1. fuel filter classification

There are three types: diesel, gasoline and natural gas. Its function is to filter out harmful particles and moisture in the engine gas system, thereby protecting the oil pump nozzle, cylinder liner, piston ring, etc. Reduce wear and avoid clogging.

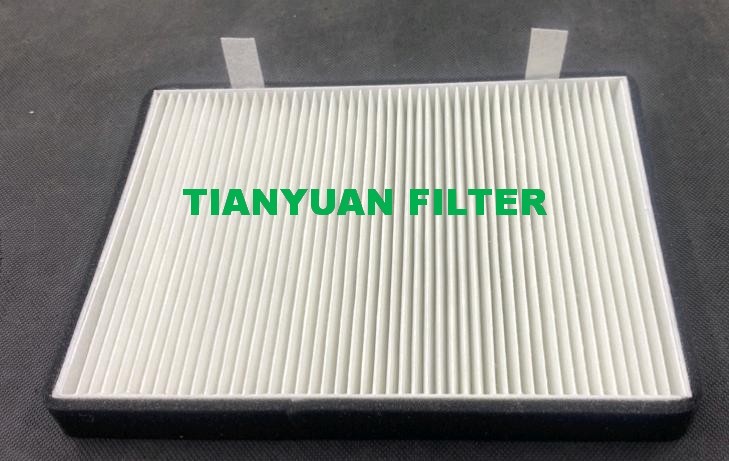

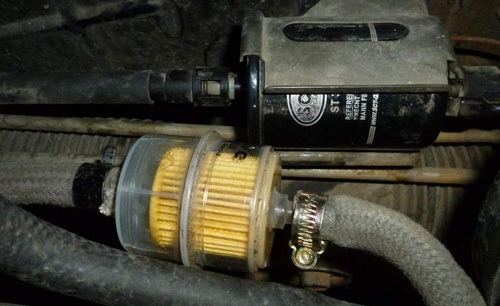

There are two types of gasoline filters: fuel tank type and electronic injection type. For gasoline engines using a carburetor, it is located on the oil inlet side of the oil pump and has a lower working pressure. Nylon casing is generally used. For EFI engines, located on the outlet side of the oil pump, the working pressure is high, and metal shells are usually used. Filter more use of filter paper, nylon cloth and polymer materials are also used.

The manufacturer of the fuel moisture clutch stated that the function of the fuel filter is to remove solid impurities such as iron oxide and dust contained in the fuel and prevent the fuel system from clogging (especially the fuel nozzle). Reduce mechanical wear, ensure stable operation of the engine, and improve reliability.

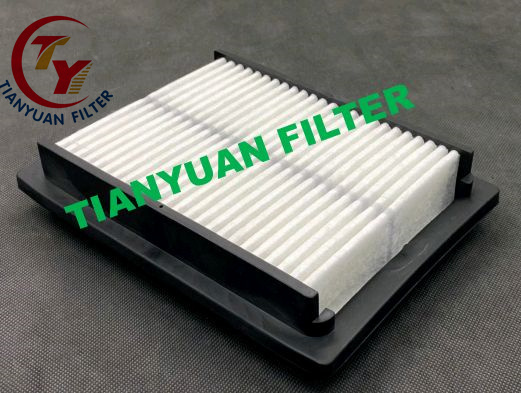

The working principle of the 2. fuel filter

Generally, there are various impurities in gasoline, and a certain amount of dirt will be deposited after the fuel tank is used for a long time. The above reasons will affect the quality of gasoline. The function of the gasoline net is to filter the above-mentioned impurities. The gasoline in the fuel tank is filtered by the gasoline net and reaches the combustion chamber of the engine, so that its clean purity can be effectively guaranteed.

Performance characteristics of 3. fuel filter

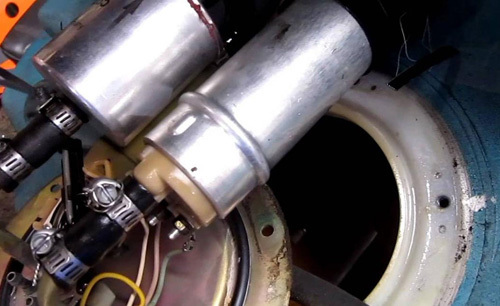

If the filter is installed in the fuel line, it is called an external filter. In contrast, internal filters refer to filters installed inside the fuel pump and fuel tank. Among them, the tank filter or its protective sleeve is generally considered to be a maintenance-free component.

The fuel filter of many imported cars uses a drum tube connection. In order to ensure the reliability of the connection and sealing, the same gasket must not be reused. In addition, even if a brand new gasket is used, the tightness after connection and fastening must be checked. When the fuel system needs to replace the "O" ring, make sure the specifications are correct, and check whether the elasticity and hardness of the ring are appropriate.

According to the introduction of the fuel moisture clutch manufacturer, the non-loop fuel system has only one internal filter (in the fuel tank), although this multi-in-one (all-in-one) pump, filter, The delivery unit is expensive, but when the fuel delivery is blocked or the engine performance drops as a result, proper maintenance and maintenance must be carried out in time. At the same time, check for faults in all fuel lines and for cracks and crimps at the hose clamps.

Oil filter

Related Products

Related News

2023-07-05

Fuel moisture clutch manufacturer: working principle and characteristics of fuel filter

2023-07-05

What is the role of the fuel moisture clutch?

2023-07-05